HOW OUR PROCESS WORKS

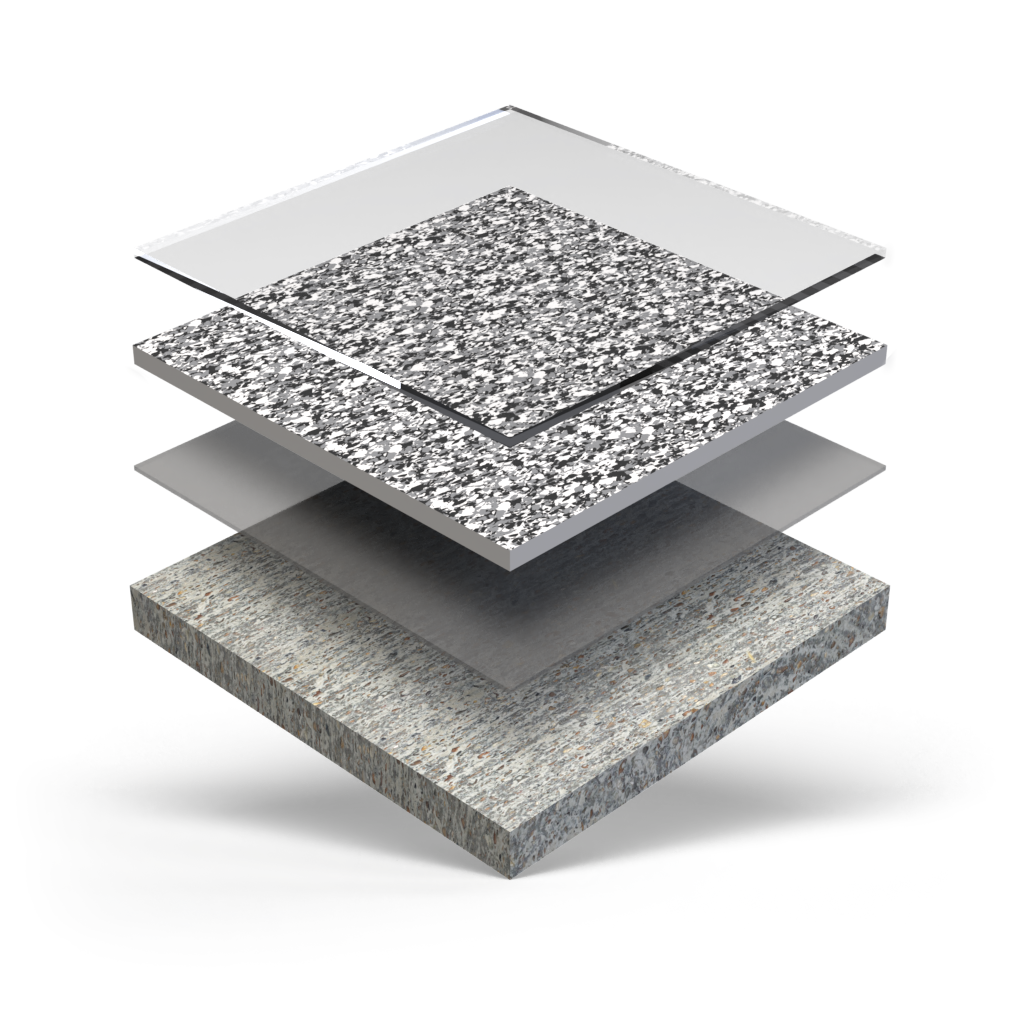

1. Grinding - This is done to remove any previous coatings on the surface, as well as to level it.

2. Repairing - Any cracks and divots in the flooring are filled in using 100 percent solids. The surface is then ground down and smoothed to prepare for the epoxy coating.

3. Coating - We use a self-priming fast cure epoxy based primer with a moisture barrier built in.

4. Flaking - The base coat is flaked by hand with a full broadcast coverage. Any excess flakes are discarded to make for a level surface.

5. Sealing - We use a fast-drying Polyaspartic topcoat to make it shine and give it durability. Our products provide superior protection against stains and is UV stable.

6. Beautiful, Strong Flooring Results!